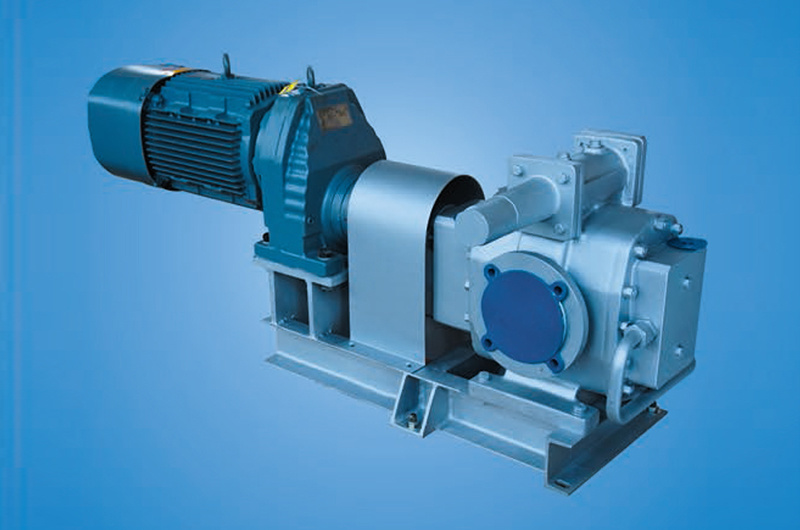

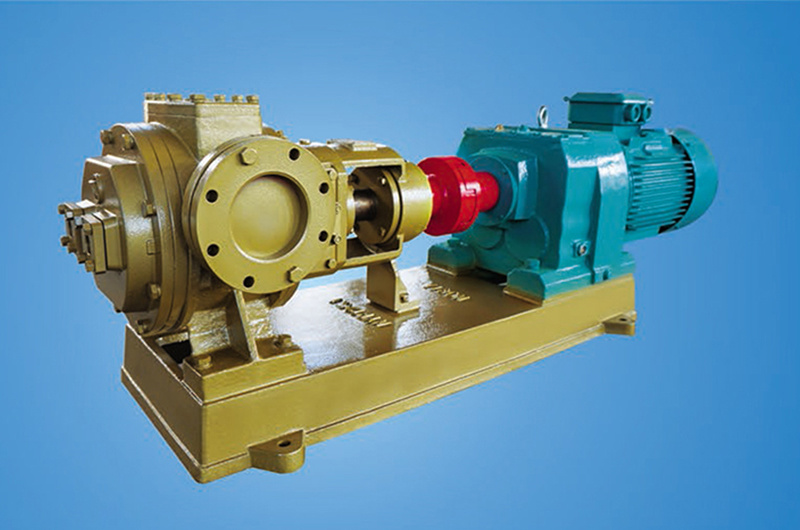

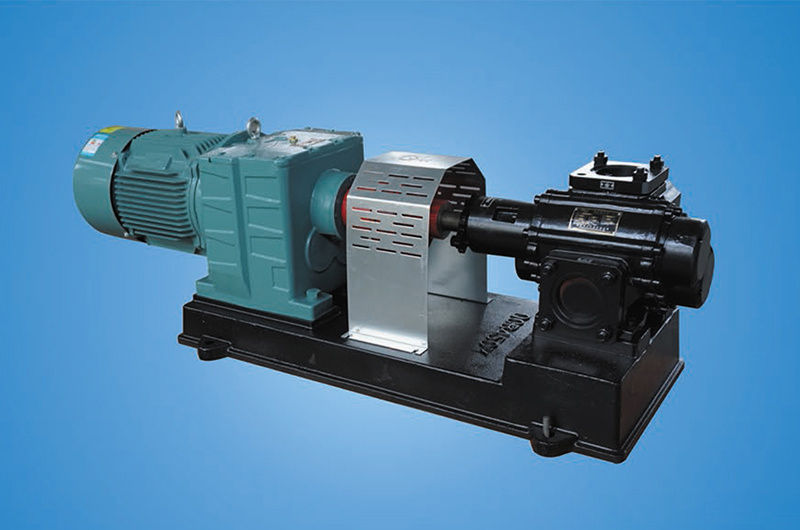

QGB Gear Pump Series

Key words:

Classification:

Keyword: QGB Gear Pump Series

E-mail:

Telephone:

Details

The main parts of the QGB series internal gear pump are a pair of gears, consisting of an arc gear and a cycloidal gear. The internal gear pump has advantages such as low noise, low flow pulsation, good suction performance, insensitivity to impurities, reliable operation with a long service life, and ease of maintenance and repair. It is particularly suitable for transporting fluids with high precision metering requirements.

High viscosity media, and is also suitable for transporting various liquids without solid particles (or solid particles ≤0.08mm), and can be used as a lubricating oil pump, fuel pump, infusion pump, and hydraulic pump, etc.

It is widely used in industries such as petroleum, chemical, pharmaceutical, food, textile, daily chemical, and highway asphalt construction.

The QGB series internal gear pump produced by our company is developed and designed based on the characteristics of high viscosity media. The cycloidal gear, arc gear, pump body, and other components are processed using machining centers, ensuring high processing accuracy and a volumetric efficiency of up to 90%. The maximum working temperature is ≤350℃. Compared with peers in the industry, it has advantages such as a very low relative sliding speed of the gear pair, low wear, low noise, strong suction capability, high discharge pressure, and compact structure.

|

Model Model Parameters Parameter |

Flow Rate Flow Rate (L/min) |

Pressure Pressure (MPa) |

Rotate Speed Rotate Speed (r/min) |

NPSHr NPSHr (m) |

Inlet and Outlet Size Inlet and Outlet Size (mm) |

Motor Model and Power Motor Model and Power (kW) |

Medium Temperature Medum Temperature (℃) |

Transmission Distance Transmision Distance |

|

(m) |

||||||||

|

QGB200/0.6 |

200 |

0.6 |

710 |

3 |

40 |

Y2-132M-8/3 |

300 |

60 |

|

QGB230/1.0 |

230 |

1.0 |

388 |

2.5 |

50 |

Y2-132M-4/7.5 |

300 |

100 |

|

QGB270/0.8 |

270 |

0.8 |

Y2-132M2-6/5.5 |

300 |

80 |

|||

|

QGB310/0.6 |

310 |

0.6 |

Y2-132M2-6/5.5 |

300 |

60 |

|||

|

QGB320/1.0 |

320 |

1.0 |

584 |

3 |

Y2-160M-4/11 |

300 |

100 |

|

|

QGB360/0.8 |

360 |

0.8 |

Y2-132M-4/7.5 |

300 |

80 |

|||

|

QGB400/0.6 |

400 |

0.6 |

Y2-132M2-6/5.5 |

300 |

60 |

|||

|

QGB420/1.0 |

420 |

1.0 |

388 |

2.5 |

80 |

Y2-160L-6/11 |

300 |

100 |

|

QGB450/0.8 |

450 |

0.8 |

Y2-160L-6/11 |

300 |

80 |

|||

|

QGB480/0.6 |

480 |

0.6 |

Y2-160M-6/7.5 |

300 |

60 |

|||

|

QGB600/1.0 |

600 |

1.0 |

584 |

3 |

Y2-180M-4/18.5 |

300 |

100 |

|

|

QGB640/0.8 |

640 |

0.8 |

Y2-160L-4/15 |

300 |

80 |

|||

|

QGB680/0.6 |

680 |

0.6 |

Y2-160L-6/11 |

300 |

60 |

|||

|

QGB540/1.0 |

540 |

1.0 |

388 |

2.5 |

100 |

Y2-180M-4/18.5 |

300 |

100 |

|

QGB580/0.8 |

580 |

0.8 |

Y2-180L-6/15 |

300 |

80 |

|||

|

QGB620/0.6 |

620 |

0.6 |

Y2-160L-6/11 |

300 |

60 |

|||

|

QGB870/1.0 |

870 |

1.0 |

584 |

3 |

Y2-180L-4/22 |

300 |

100 |

|

|

QGB920/0.8 |

920 |

0.8 |

Y2-180M-4/18.5 |

300 |

80 |

|||

|

QGB950/0.6 |

950 |

0.6 |

Y2-180L-6/15 |

300 |

60 |

|||

|

QGB770/1.0 |

770 |

1.0 |

200 |

125 |

Y2-180L-4/22 |

300 |

100 |

|

|

QGB800/0.8 |

800 |

0.8 |

Y2-160L-4/15 |

300 |

80 |

|||

|

QGB830/0.6 |

830 |

0.6 |

Y2-160L-4/15 |

300 |

60 |

|||

|

QGB1150/1.0 |

1150 |

1.0 |

300 |

Y2-200L-4/30 |

300 |

100 |

||

|

QGB1200/0.8 |

1200 |

0.8 |

Y2-180L-4/22 |

300 |

80 |

|||

|

QGB1230/0.6 |

1230 |

0.6 |

Y2-180M-4/18.5 |

300 |

60 |

|||

|

QGB1600/0.6 |

1600 |

0.6 |

388 |

Y2-200L-4/30 |

300 |

60 |

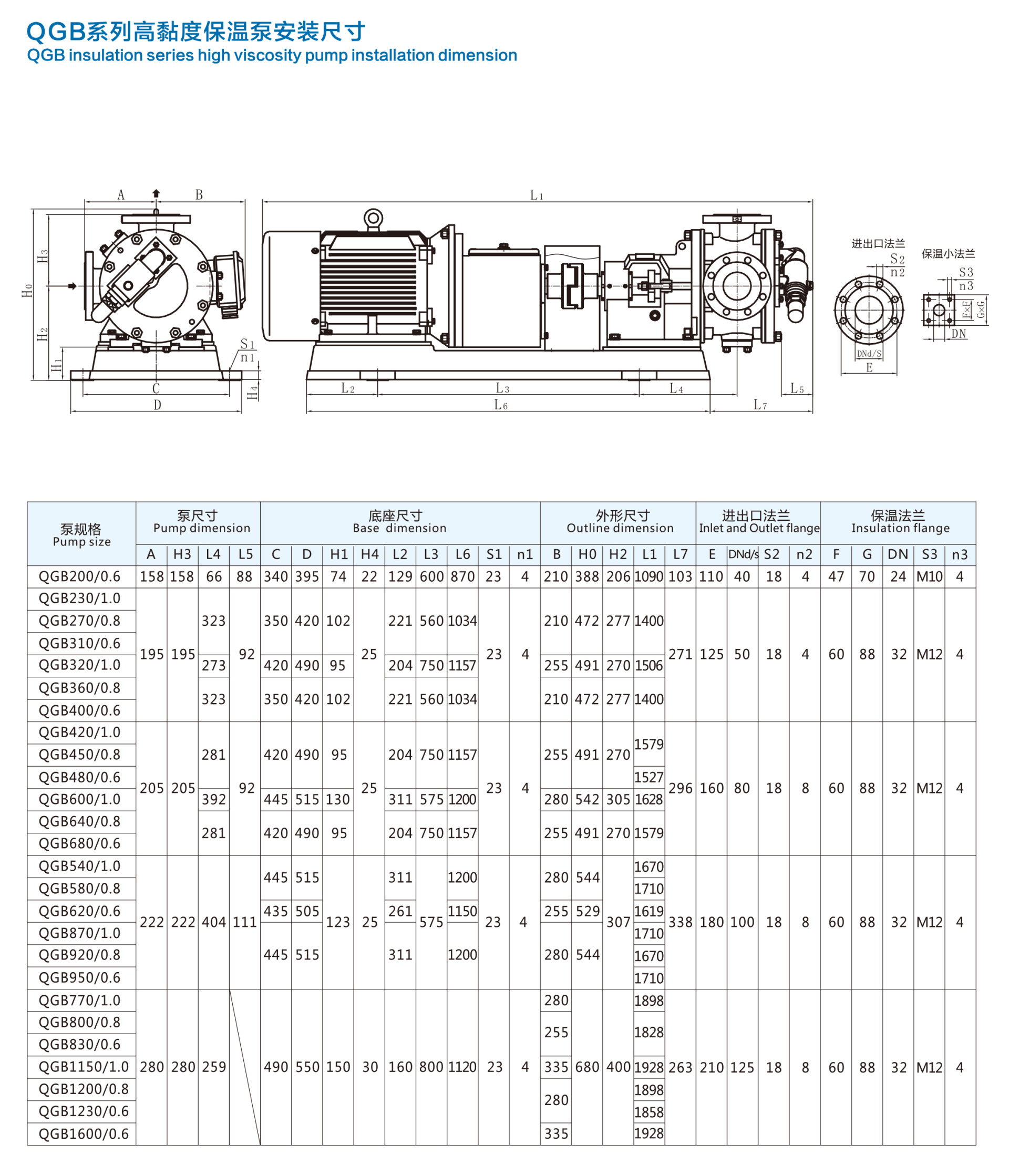

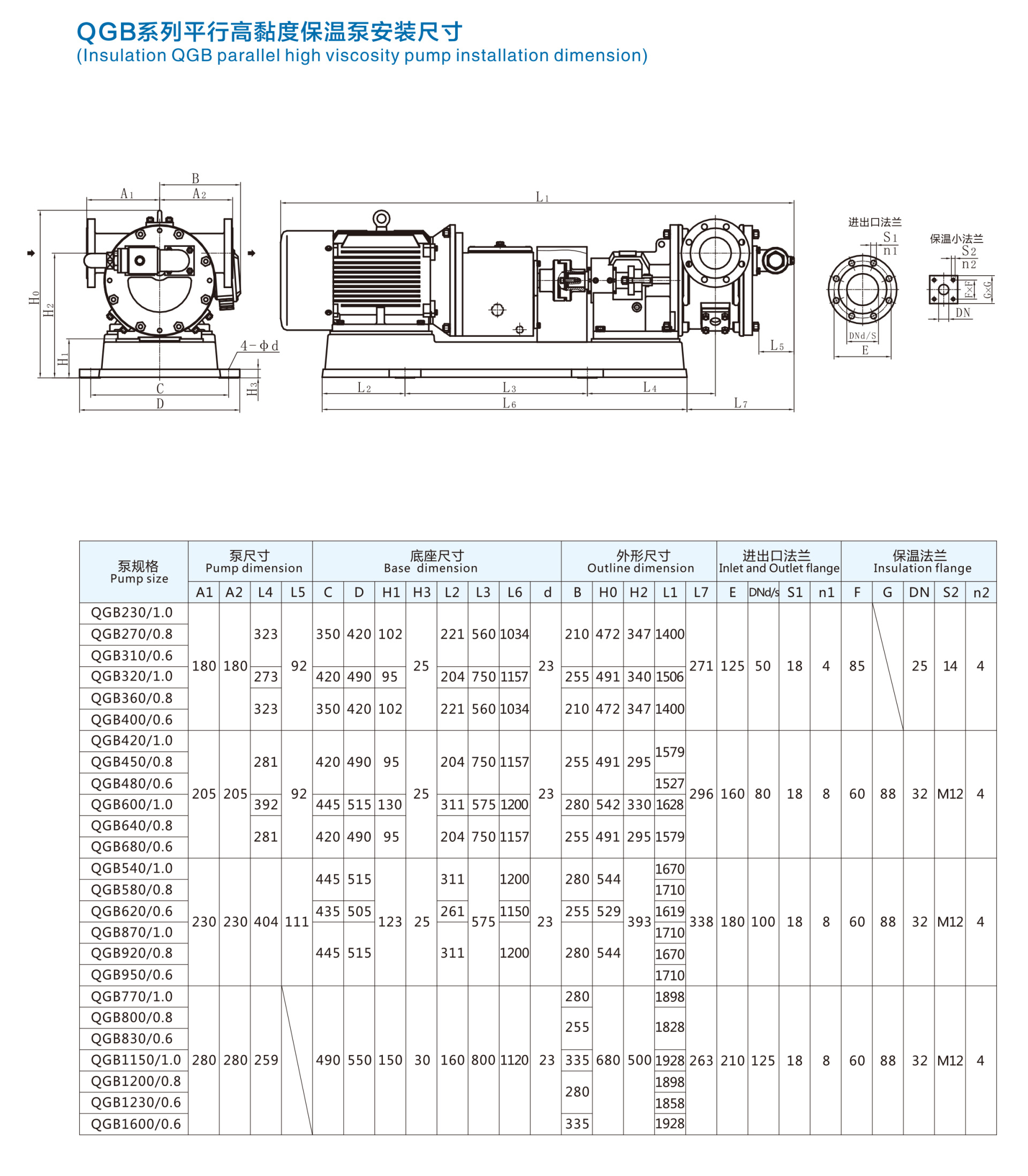

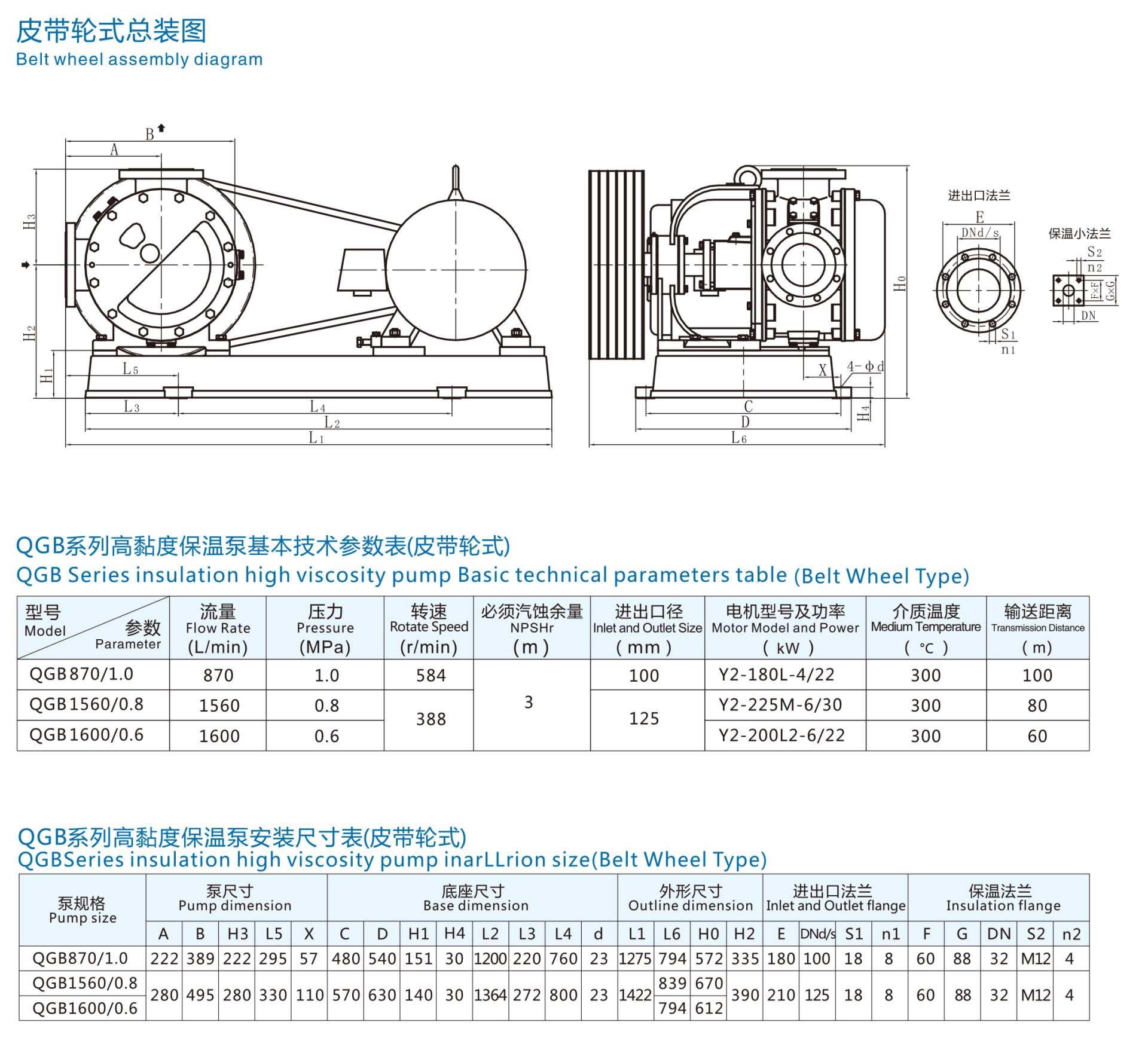

a simple structure and stable performance. Both the front and rear of the pump are equipped with insulation chambers, allowing gas or liquid to be used as a heat carrier to heat and insulate the pump, making it particularly suitable for transporting high-viscosity media. This series of insulated gear pumps has two inlet and outlet configurations: left inlet and right outlet, and right inlet and left outlet, with the same installation dimensions and strong interchangeability.

Related Products

Online message

* Leave your contact information to get a product quote