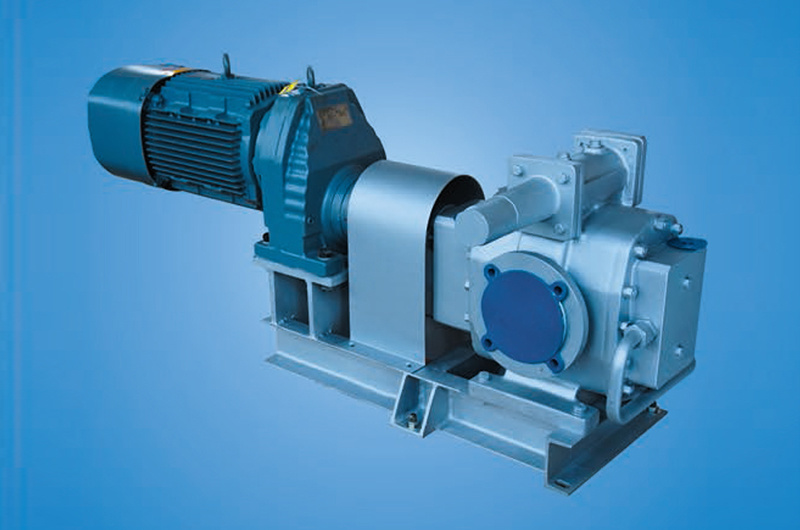

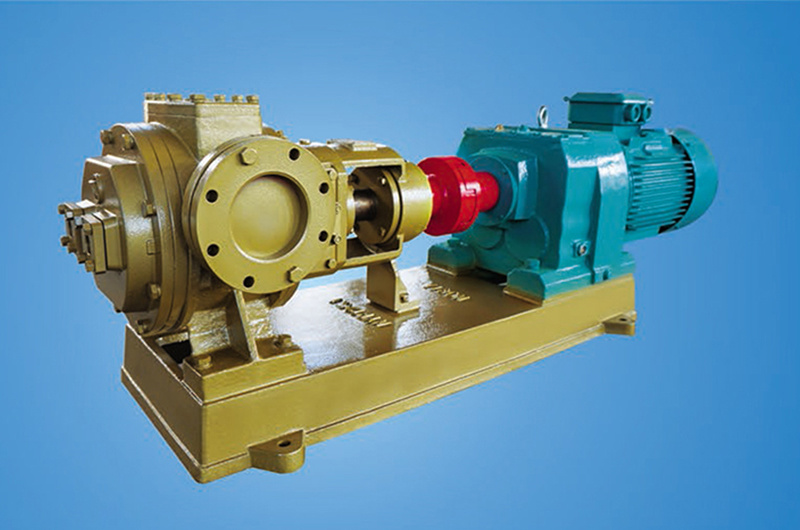

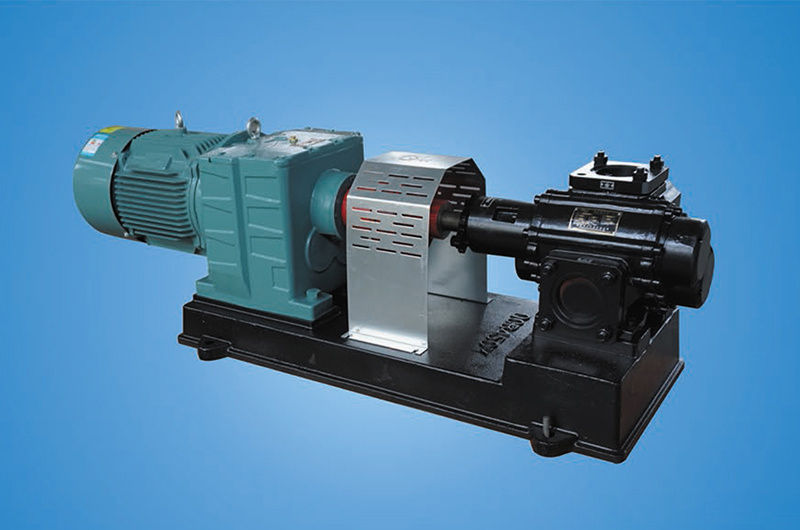

RCB helical gear pump

Key words:

Classification:

Keyword: RCB helical gear pump

E-mail:

Telephone:

Details

Overview

The helical gear not only has the advantages of bevel gears but also overcomes the disadvantage of bevel gears generating large axial forces. The company has designed and developed the RCB series helical gear pump based on helical gear transmission. The developed RCB helical gear pump has continuous point contact between the tooth profiles during the engagement of the two gears, which prevents the phenomenon of oil trapping, solving issues such as pump vibration, noise, and increased bearing load caused by oil trapping in gear pumps. Therefore, the RCB helical gear pump has advantages such as high efficiency and low noise, and it also has good energy-saving effects.

The RCB helical gear pump is mainly used for transporting high-viscosity lubricating liquids. The viscosity of the transported medium ranges from 3.0 to 760 mm/s. It is commonly used as a transport pump for asphalt, heavy fuel oil, heavy gear oil, and heavy diesel. It has the following advantages:

1. Compact structure: Under the same flow conditions, the RCB helical gear pump can be made smaller due to the larger helix angle of the gears, making the structure more reasonable and compact.

2. Stable operation, low noise: The engagement of the gears in the RCB helical gear pump is a smooth engagement, so the pump operates smoothly and quietly.

3. Self-protection function: In case of system issues or oil line blockage, the pump has a safety valve that allows the medium discharged by the pump to flow back to the low-pressure side, thus protecting the pump and system from damage due to excessive pressure.

4. Long service life: The special structural form of the helical gear pump results in lower fatigue loads during operation, thereby increasing the service life of the pump.

Basic technical parameters table for RCB series high-viscosity insulation pumps

| Model | Parameters | Flow Rate Flow Rate (L/min) | Pressure Pressure (MPa) | Rotate Speed Rotate Speed (r/min) | NPSHr NPSHr (m) | Shaft Power Shaft Power (kW) | Motor Model and Power Motor Model and Power (kW) |

RCB200 | 600 | 0.6 | 300 |

3 | 8.06 | R97-160M-4/11 | |

| 920 | 0.4 | 460 | 8.29 | R87-160M-4/11 | |||

| 1000 | 0.4 | 529 | 9.0 | RX87-160M-4/12 | |||

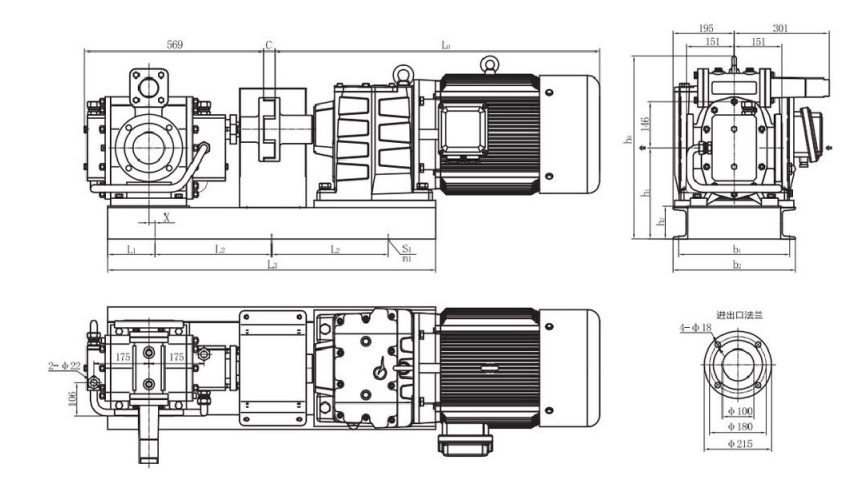

RCB series installation dimensions

Pump Size Pump Size | Reducer Specification Reducer Specifications | Inlet and Outlet Installation Dimensions instalaionsle | Outline Installation Size | |||||||||||

| X | h₁ | h. | h₂ | C | Lo | L1 | L2 | L₃ | b₁ | b₂ | S1 | n1 | ||

RCB200 | RX87 | 99 | 283 | 614 | 98 | 25 | 871 | 23 | 325 | 793 | 324 | 360 | 16 | 4 |

| R87 | 5 | 250 | 517 | 65 | 25 | 1047 | 120 | 600 | 875 | 368 | 405 | 14 | 4 | |

| R97 | 20 | 290 | 583 | 105 | 35 | 1032 | 150 | 370 | 1040 | 353 | 390 | 14 | 6 | |

a simple structure and stable performance. Both the front and rear of the pump are equipped with insulation chambers, allowing gas or liquid to be used as a heat carrier to heat and insulate the pump, making it particularly suitable for transporting high-viscosity media. This series of insulated gear pumps has two inlet and outlet configurations: left inlet and right outlet, and right inlet and left outlet, with the same installation dimensions and strong interchangeability.

Related Products

Online message

* Leave your contact information to get a product quote