SGX type rubber modified asphalt equipment

Key words:

Classification:

Keyword: SGX type rubber modified asphalt equipment

E-mail:

Telephone:

Details

According to statistics, in 1988, the number of cars in China was 1.627 million, and by 2007, it reached 55 million. Experts from the China Association of Automobile Manufacturers predict that by 2020, it will reach 600 million. In 2006, the number of waste tires reached 150 million, approximately 3.24 million tons, and is expected to rise at a rate of 20% per year, reaching 200 million, approximately 5.18 million tons by 2018.

Background of rubber asphalt:

A large number of waste tires accumulate, occupying land resources.

Burning waste tires causes environmental pollution.

Accumulation of tires breeds mosquitoes, accelerating the spread of diseases.

600.6 waste truck tires.

18.2 tons of rubber powder.

101 tons of rubber asphalt.

1 kilometer of rubber asphalt pavement.

(4 lanes, 4cm surface layer, oil-stone ratio 7.5)

History of rubber asphalt:

In the 1960s, rubber asphalt was officially born in the United States.

In 1960, the first rubber asphalt seminar was held in Chicago.

In 1975, California began research on rubber asphalt chip sealing and gradually promoted its use.

In 1978, the first dry method rubber-treated asphalt concrete pavement was built in California.

In 1982, Tongji University in China conducted a trial road in Jiangxi, marking the beginning of tire rubber use in domestic roads.

In 1992, the California Department of Transportation issued the "Guidelines for the Design of Rubber Asphalt Gradation Mixes."

In 1993, the patent for rubber asphalt technology expired, leading to widespread promotion and application of rubber asphalt globally.

In 2001, the Ministry of Transport of China established two special projects under the Western Science and Technology Program: "Application of Waste Rubber Powder in Highway Engineering" and "Research on Rubber Particle Pavement Application Technology."

In 2004, we successfully advanced the first set of rubber asphalt production equipment, and the industrialization project of rubber asphalt was fully launched.

In 2008, Wang Xudong and others compiled the "Complete Technology for Rubber Asphalt and Concrete Applications" based on the Ministry of Transport's Western Science and Technology Program, published by the People's Transportation Publishing House.

In 2008, the Highway Scientific Research Institute of the Ministry of Transport of China edited the "Technical Guidelines for the Design and Construction of Rubber Asphalt and Mixtures," published by the People's Transportation Publishing House, marking a significant milestone in the development of rubber asphalt in China.

Performance characteristics:

1. Environmental protection and resource conservation.

While China's economy is developing rapidly, it has also brought a large number of waste tires, causing serious pollution to the social environment. The promotion and application of rubber asphalt technology, with its characteristics of environmental protection and resource conservation, can provide a sustainable environmental solution to this black pollution.

2. Delay and resist reflective cracking.

Rubber asphalt has a high binder content and good elasticity, improving the resistance to fatigue and reflective cracks on the road surface. The rubber asphalt stress-absorbing layer (SAMI) is internationally recognized as the most effective solution to resist reflective cracking.

3. Super strong bonding effect, resistant to water damage.

The rubber asphalt stress-absorbing layer forms a waterproof layer about 3mm thick on the original pavement, completely preventing rainwater from penetrating downwards, thus protecting the underlying layer.

4. Resistance to high-temperature rutting.

Rubber asphalt itself has strong high-temperature stability and viscosity, and all rubber asphalt binders have high viscosity and are not easily flowable. Additionally, the rubber asphalt binder wrapped around the gravel layer contains large particles of rubber powder, which can generate significant internal friction resistance, making it difficult for the gravel to slide, thus reducing rutting formation while ensuring structural capacity.

5. Resistance to low-temperature cracking.

Due to the plasticity and ductility of rubber itself, the low-temperature ductility of rubber asphalt is increased, greatly enhancing the ability of rubber asphalt pavements to resist low-temperature cracking.

6. Noise reduction.

Rubber asphalt is a new material for reducing noise on urban roads. Compared to ordinary asphalt, it can reduce driving noise by 3-6 decibels, improving the comfort of the living environment. Rubber asphalt roads are internationally recognized as the quietest roads.

7. Improved driving safety.

The carbon black in rubber can help the road surface maintain its black color for a long time, providing high contrast with road markings, increasing road friction, and enhancing braking resistance, thus improving driving safety, especially on snowy or wet surfaces.

8. Reduced pavement thickness, shortened construction period, and lowered construction costs.

Whether for load-bearing capacity standards or reducing reflective cracking standards, the thickness of the rubber asphalt concrete surface can be reduced by about 30%. When using the rubber asphalt stress-absorbing layer in the asphalt structural layer, the thickness can be further reduced, resulting in an overall cost reduction of 13-17% compared to ordinary asphalt.

9. Anti-aging performance, extended service life, and reduced maintenance costs.

In the formulation of rubber for tire production, a large number of anti-aging agents, thermal stabilizers, metal deactivators, UV absorbers, and light shielding agents have been added. These anti-aging agents, combined with the highly effective light shielding carbon black fillers, are released into the asphalt during the mixing process, greatly improving the anti-aging and oxidation resistance of the asphalt mixture, thus enhancing the durability of the road and extending its lifespan (the lifespan of roads can be extended by 1-3 times compared to ordinary asphalt), significantly reducing maintenance costs.

List of configurations and parameters for SGX type rubber modified asphalt equipment:

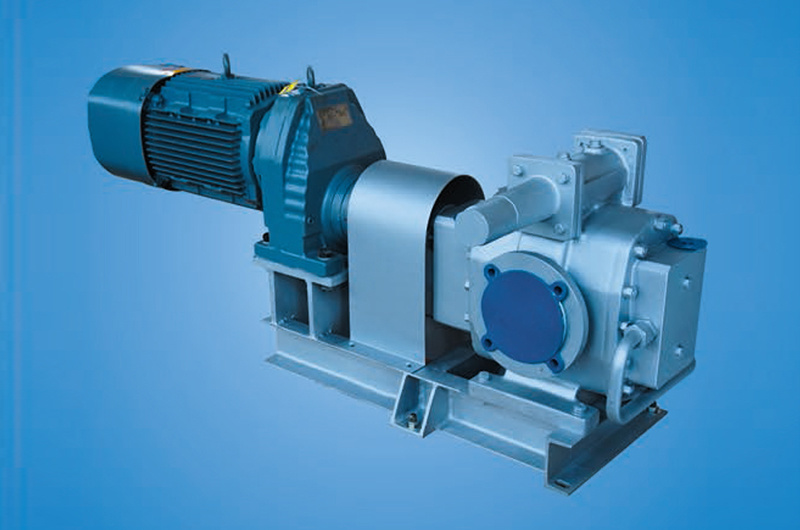

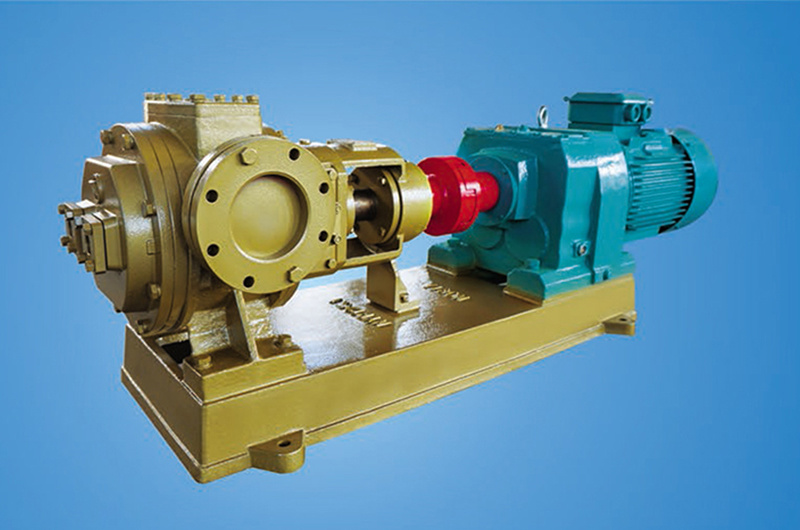

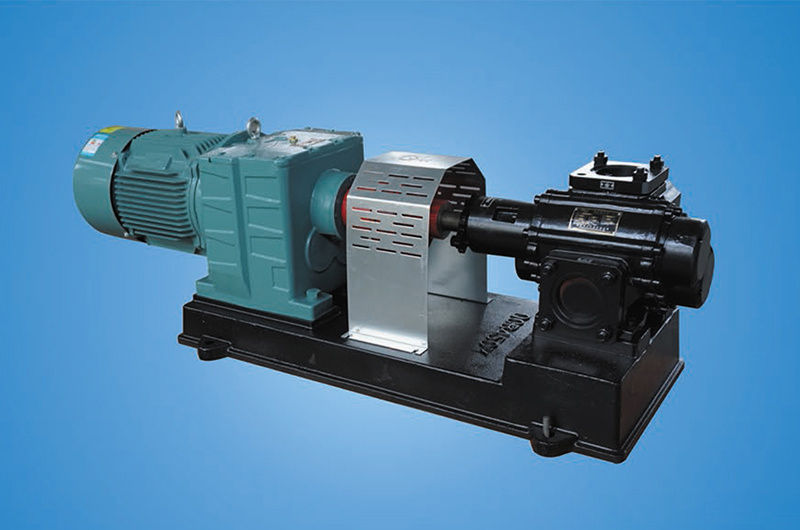

a simple structure and stable performance. Both the front and rear of the pump are equipped with insulation chambers, allowing gas or liquid to be used as a heat carrier to heat and insulate the pump, making it particularly suitable for transporting high-viscosity media. This series of insulated gear pumps has two inlet and outlet configurations: left inlet and right outlet, and right inlet and left outlet, with the same installation dimensions and strong interchangeability.

Related Products

Online message

* Leave your contact information to get a product quote