SG modified asphalt equipment

Key words:

Classification:

Keyword: SG modified asphalt equipment

E-mail:

Telephone:

Details

The SG series modified asphalt equipment is a high-quality and highly reliable modified asphalt processing equipment launched by our company after comprehensive performance analysis and comparison of various domestic and imported modification processing equipment, combining the strengths of many manufacturers, along with our company's rich experience accumulated over twenty years in the fields of asphalt transportation, polymer modified asphalt grinding, and finished product nurturing and storage. The equipment has a high degree of automation, simple operation, and a clear interface flow, and it reserves other polymer modified asphalt processing functions.

Composition of the complete set of modified asphalt equipment:

The SG series modified asphalt equipment is suitable for producing various polymer modified asphalts, with modifiers such as SBS, SBR, EVA, PE, etc.

The equipment mainly consists of swelling stirring, instant heating, metering, grinding, finished product nurturing, electrical control, and other systems.

Application range:

Mainly applied to high-grade highways, first-class roads, and airport runways, etc.

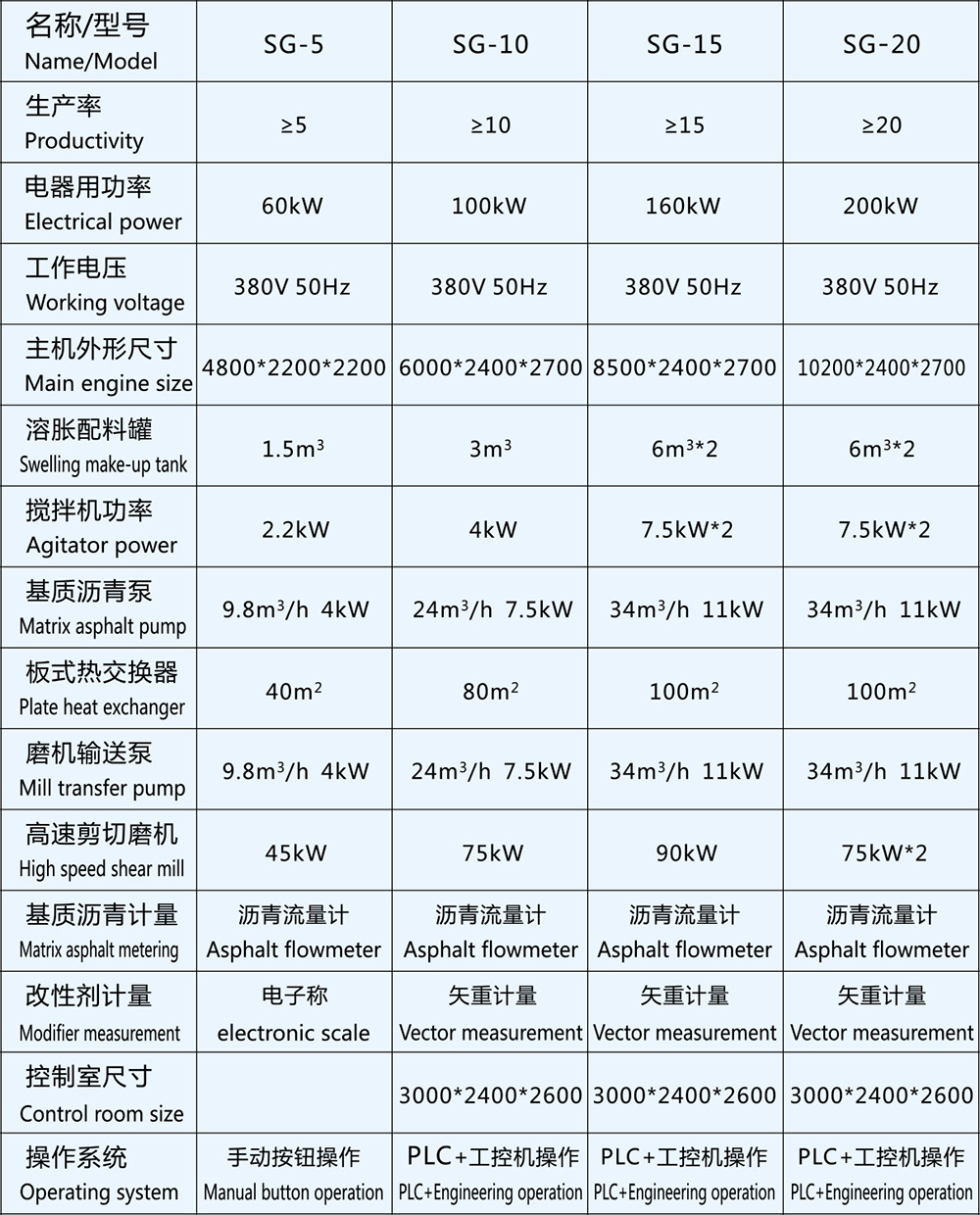

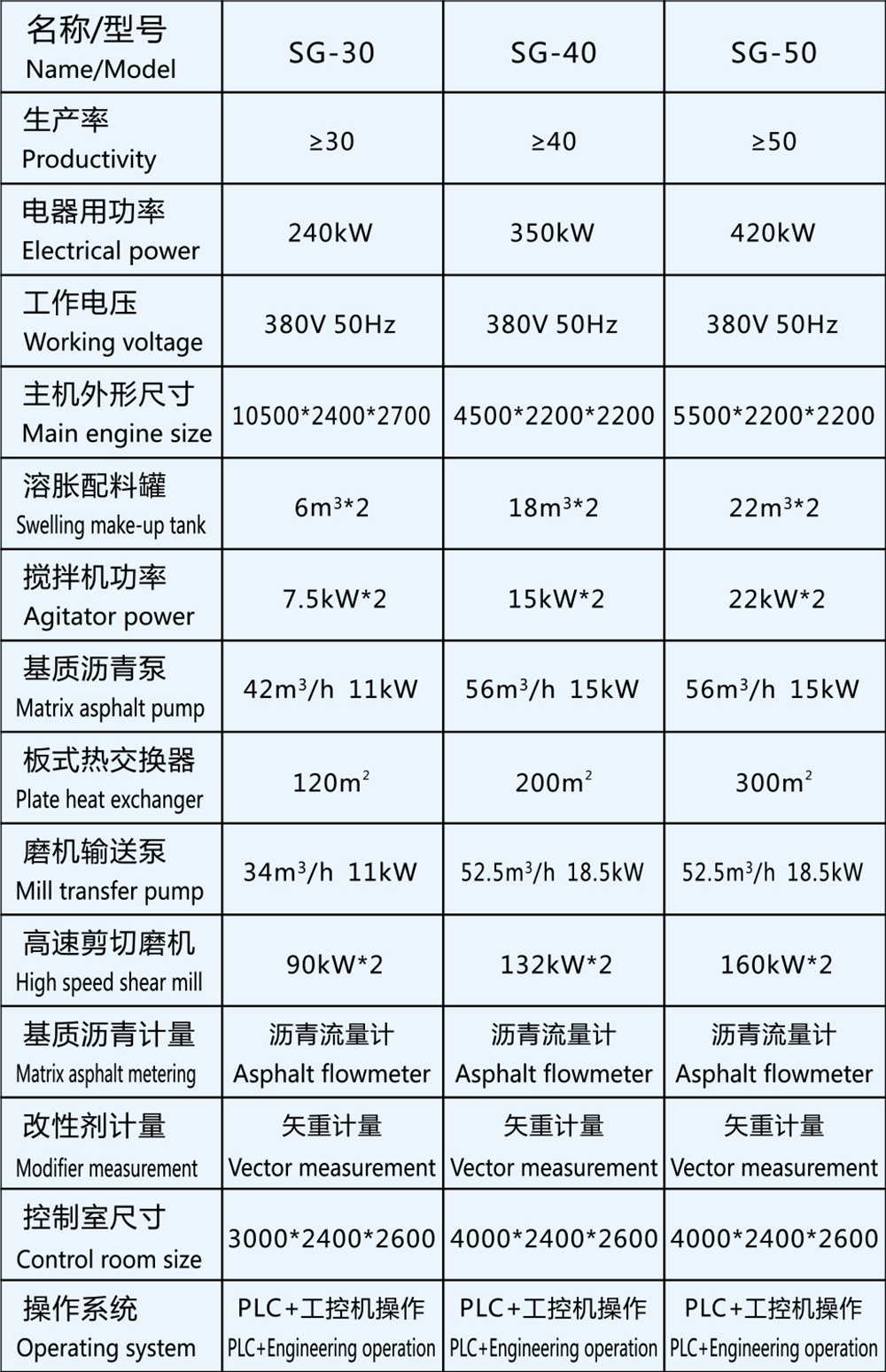

Configuration list and parameters of SG mobile modified asphalt equipment:

Configuration list and parameters of SG fixed modified asphalt equipment:

1. Swelling stirring system

The swelling mixing tank of this equipment uses a channel steel guide flow type heat transfer oil circulation heating method. Through specific design of the tank body and stirring blades, there are no dead corners inside the tank, ensuring thorough stirring without clogging. The stirrer uses a grease-lubricated cycloidal pinwheel reducer, which has high output efficiency, strong environmental resistance, and a long maintenance-free period. The tank is equipped with a pressure sensor designed for high-temperature and high-viscosity liquid level detection, and the human-machine interaction operation interface allows for intuitive observation of the liquid level status inside the tank. The tank body is equipped with temperature sensors, liquid level limiters, valve signal sensors, and other functions, ensuring high safety performance.

2. Heating system

This system consists of an asphalt pump, frequency converter, temperature sensor, heat exchanger, and corresponding valves and pipelines. Under automatic constant temperature program control, the temperature difference between the inlet and outlet of the heat exchanger measured by the temperature sensor is compared. Through PID closed-loop control, the asphalt pump is continuously adjusted to achieve a constant output of the set asphalt temperature. The asphalt is heated in a closed environment for a short time, preventing asphalt aging.

3. Metering system

The metering of asphalt is done by a high-precision asphalt flow meter, which converts the mechanical data of the flow meter counter into pulse electrical signals. The PLC receives the pulse signals and calculates them through a high-speed counter, automatically stopping the asphalt feeding pump when the set asphalt value is reached. The modifier is composed of a metering tank and a weighing module, where the signal from the weighing module is amplified by an amplifier. The PLC receives the amplified signal and calculates according to the program, setting the required addition amount, and automatically stopping when the set value is reached. The additive metering and asphalt metering are similar, added as needed, and the above process automatically enters the next feeding program.

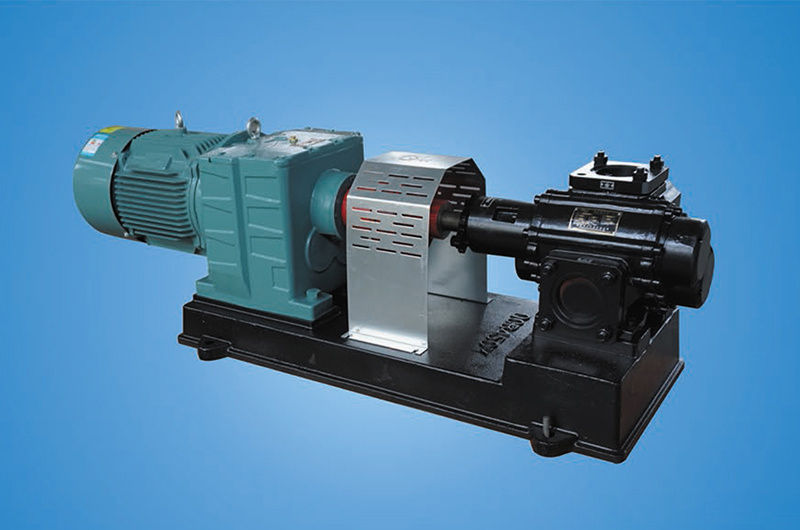

4. Grinding system

By reasonably adding a high-viscosity modified asphalt mixture delivery pump and two high-speed shear colloid mills in series, a modified asphalt grinding system is formed. The grinding process achieves very ideal results after two high-speed shear grindings through two mills. The dynamic and static discs of the high shear grinder are newly designed, allowing the asphalt mixture to perform a zigzag motion pattern in the grinding chamber, undergoing countless shear and grinding in a very short time, improving the refinement and production efficiency of modified asphalt.

5. Control system

An imported PLC and a human-machine interaction operation interface developed with force control are selected, displaying the matrix asphalt temperature, real-time asphalt metering, real-time modifier metering, dynamic liquid level display, real-time additive metering, and an intuitive production process. The operation interface is clear and straightforward. It is equipped with asphalt density correction, liquid level upper limit alarm control, and the grinding mill delivery pump and high-speed shear grinder are equipped with frequency converters. The PLC controls the automatic adjustment of the current, system data can be set, and all data for production batches is automatically saved for easy querying. The production report is equipped with a printing function, and the continuous production process has high efficiency and stable, reliable performance.

6. Finished product nurturing system

The produced modified asphalt is stored in the finished product nurturing tank, where it is continuously stirred and nurtured, with the addition of stabilizers through experimental formulations to ensure that the modified asphalt has good thermal storage stability.

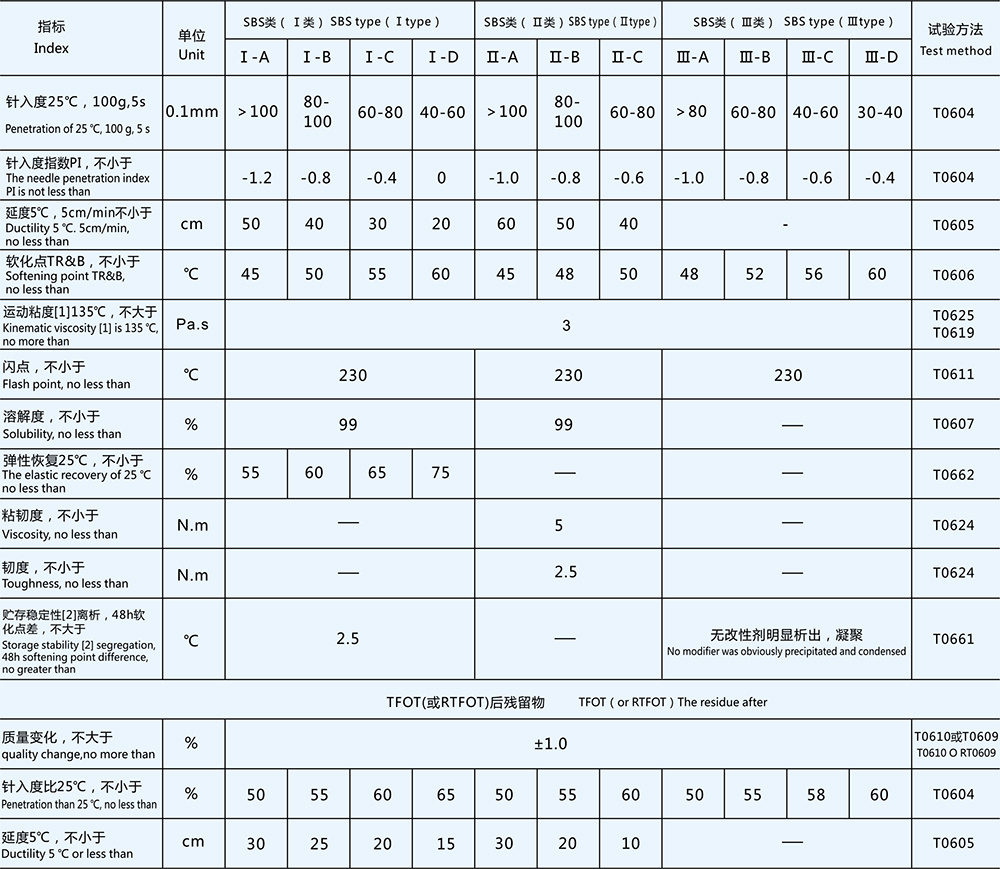

Introduction to modified asphalt

Modified asphalt can be made using high molecular polymers, natural asphalt, and other modified materials either separately or in combination. The quality of various types of polymer modified asphalt should meet the technical requirements in the table. When using polymers and composite modified asphalt not listed in the table, technical requirements can be formulated through experimental research.

Technical requirements for modified asphalt

Note:

1. The kinematic viscosity at 135°C in the table can be measured using the "Test Methods for Asphalt and Asphalt Mixtures in Highway Engineering" (JTJ052-2000) under the "Asphalt Brookfield Rotational Viscosity Test Method (Brookfield Viscosity Meter Method)."

If it is easy to pump and mix at temperatures that do not change the physical and mechanical properties of modified asphalt and meet safety conditions, or if it is proven that appropriately increasing the pumping and mixing temperature can ensure the quality of modified asphalt and facilitate construction, measurement may not be required.

2. The storage stability index applies to finished modified asphalt produced in factories. The modified asphalt made on-site does not have to meet the storage stability index, but must maintain continuous stirring or pumping circulation after production to ensure that there is no significant segregation before use.

.

a simple structure and stable performance. Both the front and rear of the pump are equipped with insulation chambers, allowing gas or liquid to be used as a heat carrier to heat and insulate the pump, making it particularly suitable for transporting high-viscosity media. This series of insulated gear pumps has two inlet and outlet configurations: left inlet and right outlet, and right inlet and left outlet, with the same installation dimensions and strong interchangeability.

Related Products

Online message

* Leave your contact information to get a product quote