BJ643H Series Pneumatic Insulated Three-Way Valve

Key words:

Classification:

Keyword: BJ643H Series Pneumatic Insulated Three-Way Valve

E-mail:

Telephone:

Details

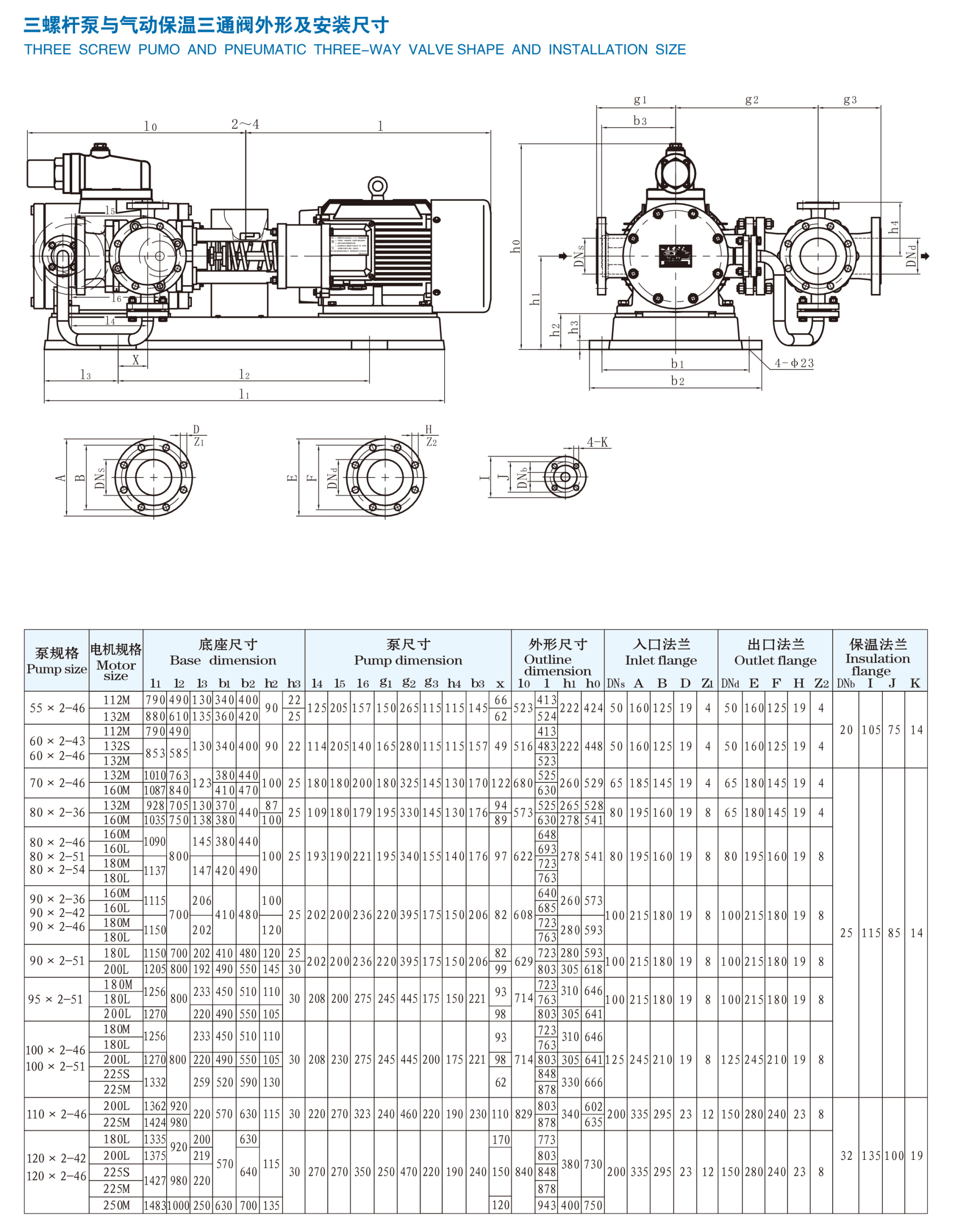

Based on the characteristics of high viscosity asphalt, the company has developed the BJ643H series pneumatic insulation three-way valve for transporting high-temperature asphalt, incorporating advanced ideas from both domestic and international sources, to significantly improve the production efficiency of asphalt systems in asphalt mixing equipment in China.

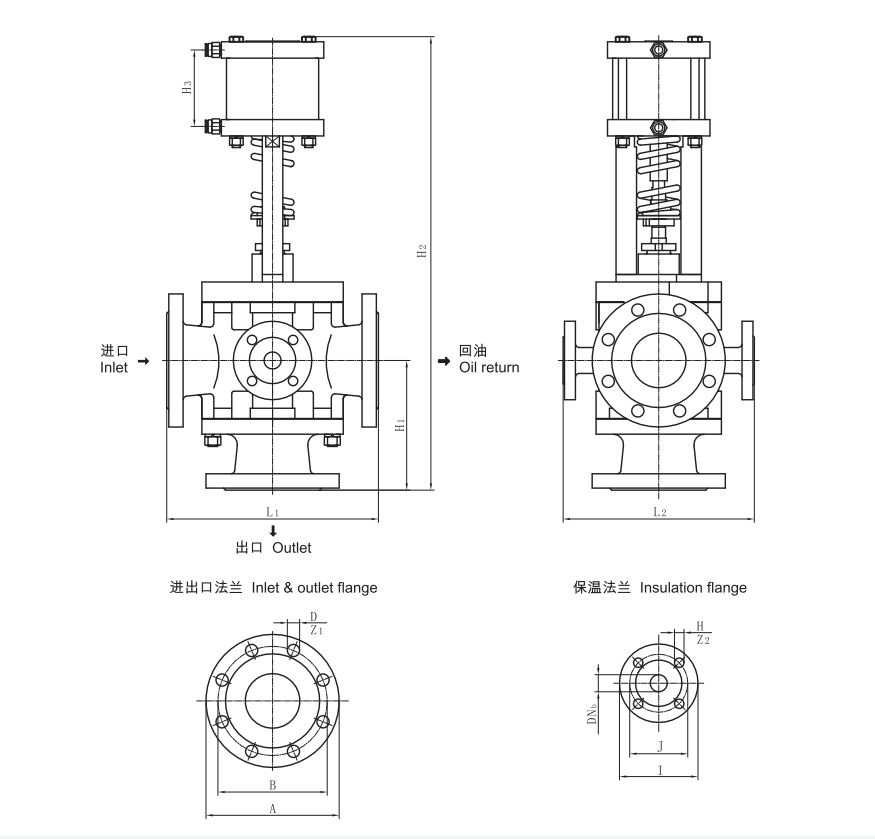

The connection structure of the BJ643H series pneumatic insulation three-way valve adopts a flange connection, and the valve body material is cast steel. The valve core is made of aluminum alloy, which automatically adjusts and repairs according to the stainless steel sealing surface of the valve body during use, thus extending its service life. The cylinder and piston are custom-designed according to the valve parameters to ensure optimal opening and closing of the valve, further extending its service life. The column and valve rod are made of stainless steel to ensure that the valve is not corroded in harsh environments and can be used normally. The spring installed on the piston rod not only ensures the valve operates between 0.3MPa and 1.0MPa pressure but also provides a buffering effect, protecting the valve core and piston, while also sealing the oil return circuit in case of air loss in the cylinder.

The BJ643H series pneumatic insulation three-way valve utilizes the piston to form two sealing chambers in the cylinder, achieving the opening and closing of the valve through the pressure difference between the two sealing chambers. Additionally, limit switches are equipped on the upper and lower covers of the cylinder, which not only ensure the displacement of the valve core but also realize automated control.

|

Nominal diameter DN Inside nominal diameter |

Installation size Installationsize |

Inlet and outlet flange Inlet and outlet flange PN16 GB/T17241.6 |

Insulation flange Insulation flange PN16 GB/T17241.6 |

|||||||||||

|

L1 |

L2 |

H1 |

H2 |

H3 |

A |

B |

D |

Z1 |

DNb |

I |

J |

H |

Z2 |

|

|

50 |

230 |

230 |

206 |

651 |

104 |

160 |

125 |

19 |

4 |

20 |

105 |

75 |

14 |

4 |

|

65 |

290 |

260 |

180 |

650 |

114 |

180 |

145 |

19 |

4 |

25 |

115 |

85 |

14 |

4 |

|

80 |

310 |

280 |

190 |

665 |

112 |

195 |

160 |

19 |

8 |

25 |

115 |

85 |

14 |

4 |

|

100 |

350 |

300 |

200 |

716 |

122 |

215 |

180 |

19 |

8 |

25 |

115 |

85 |

14 |

4 |

|

125 |

400 |

350 |

230 |

856 |

144 |

245 |

210 |

19 |

8 |

25 |

115 |

85 |

14 |

4 |

|

150 |

440 |

380 |

270 |

1143 |

182 |

280 |

240 |

23 |

8 |

32 |

135 |

100 |

19 |

4 |

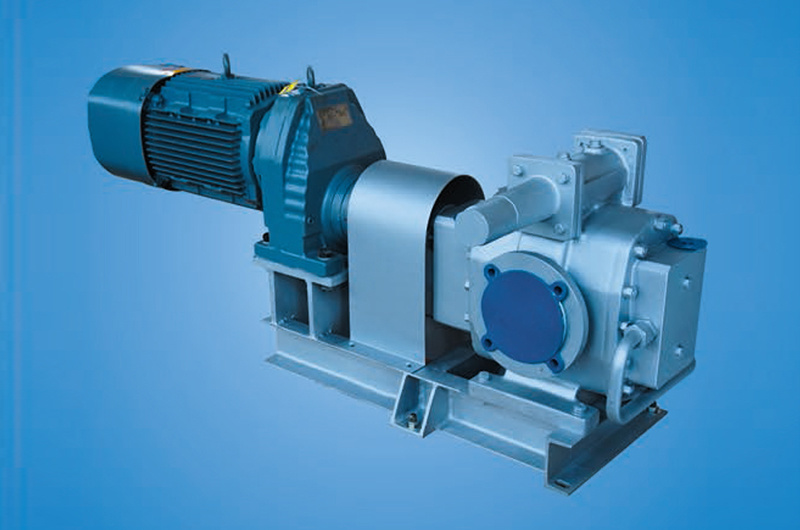

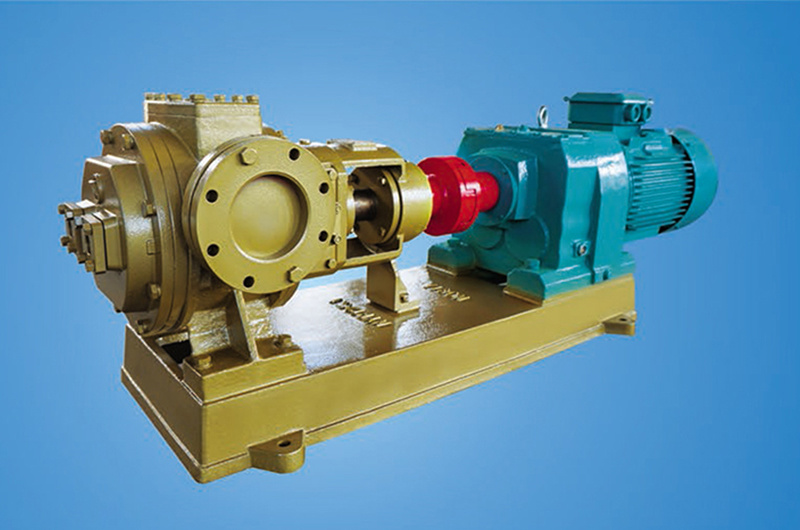

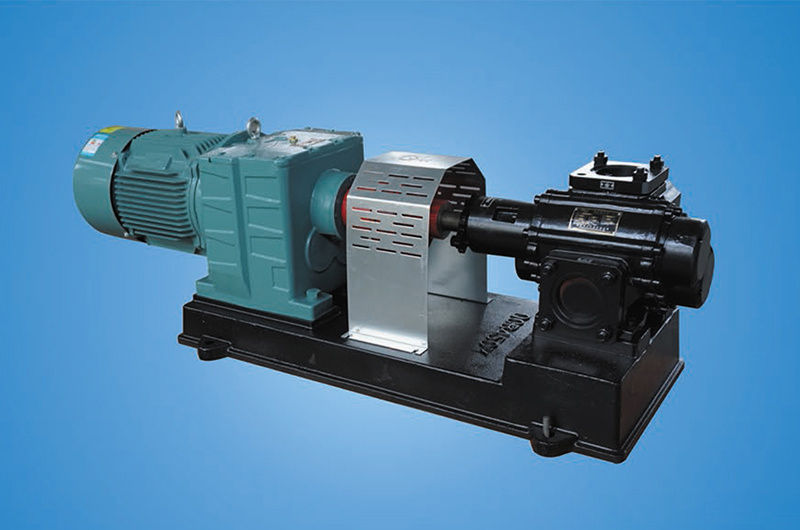

a simple structure and stable performance. Both the front and rear of the pump are equipped with insulation chambers, allowing gas or liquid to be used as a heat carrier to heat and insulate the pump, making it particularly suitable for transporting high-viscosity media. This series of insulated gear pumps has two inlet and outlet configurations: left inlet and right outlet, and right inlet and left outlet, with the same installation dimensions and strong interchangeability.

Related Products

Online message

* Leave your contact information to get a product quote