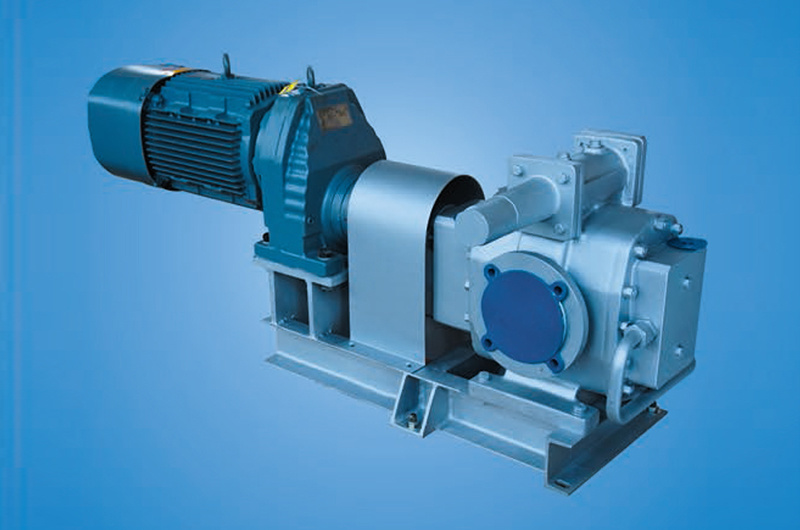

RHMJ series high-speed shear emulsifying mill

Key words:

Classification:

Keyword: RHMJ series high-speed shear emulsifying mill

E-mail:

Telephone:

Details

Overview

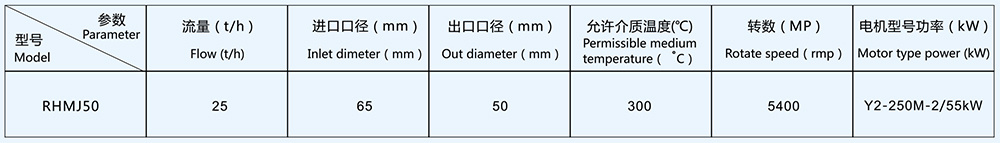

The RHMJ series high-speed shear emulsifying mill is designed by our company, absorbing advanced technologies from both domestic and international sources, specifically for the production of high-quality emulsified asphalt. It belongs to the category of advanced high-speed shear emulsifiers in the country. This mill is suitable for any emulsified asphalt production line, offering high efficiency and high quality in the production of emulsified asphalt.

All dynamic and static grinding discs of the product's components are processed using CNC lathes, while parts such as bearing seats and grinding bodies are processed using horizontal or vertical machining centers, ensuring high processing accuracy and significantly improving the mill's efficiency. Compared to peers in the industry, it has advantages such as high rotation speed, low noise, large flow, long service life, high efficiency, good quality, compact structure, and fewer components.

The main components of the RHMJ series emulsifying mill consist of a set of multi-stage stators and rotors, composed of several concentric toothed circular rings. The high tangential speed generated by the high-speed rotation of the rotor and the strong kinetic energy brought by the high-frequency mechanical effect cause the material to undergo intense mechanical and hydraulic shear, centrifugal extrusion, liquid layer friction, impact tearing, and turbulence in the narrow gap between the stator and rotor. This results in the formation of an emulsion, allowing the immiscible liquid phases to be instantaneously uniformly and finely dispersed and emulsified under the combined action of the corresponding mature process and appropriate additives, ultimately achieving a stable high-quality product through high-frequency cyclic flow.

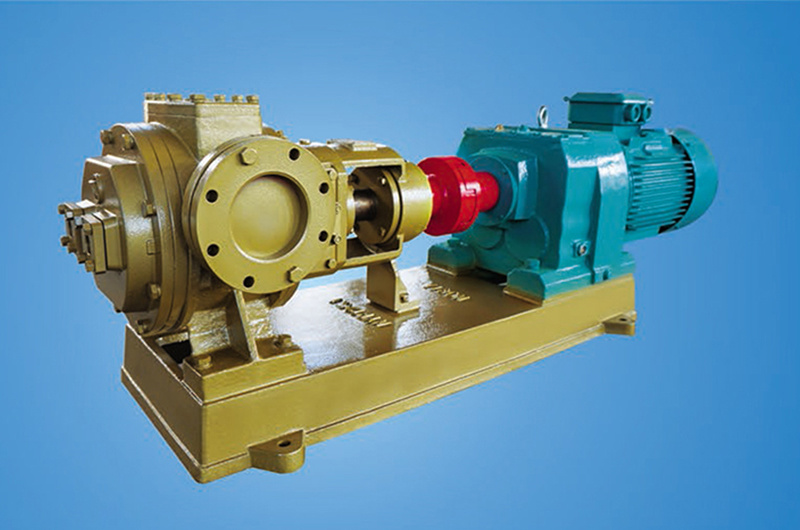

a simple structure and stable performance. Both the front and rear of the pump are equipped with insulation chambers, allowing gas or liquid to be used as a heat carrier to heat and insulate the pump, making it particularly suitable for transporting high-viscosity media. This series of insulated gear pumps has two inlet and outlet configurations: left inlet and right outlet, and right inlet and left outlet, with the same installation dimensions and strong interchangeability.

Related Products

Online message

* Leave your contact information to get a product quote