High shear homogenizing colloid mill

Key words:

Classification:

Keyword: High shear homogenizing colloid mill

E-mail:

Telephone:

Details

Overview

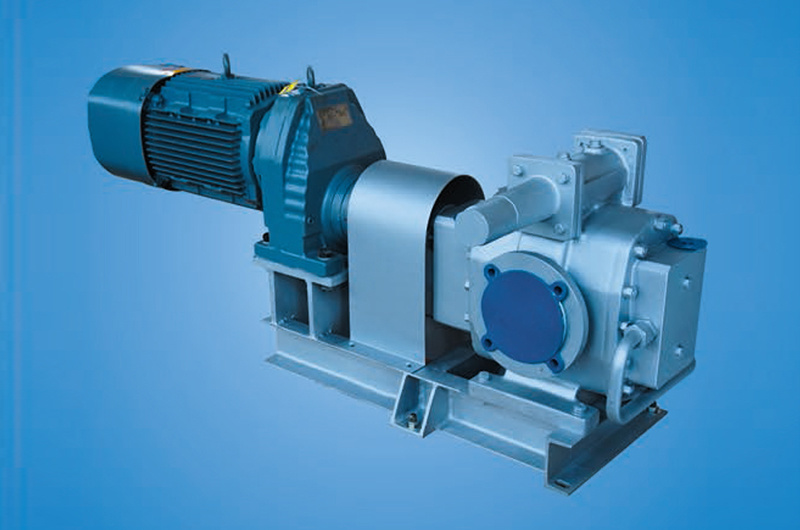

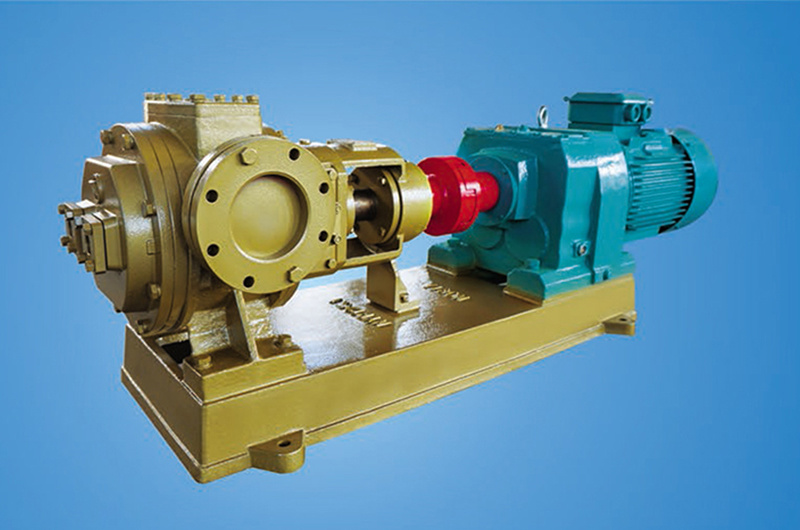

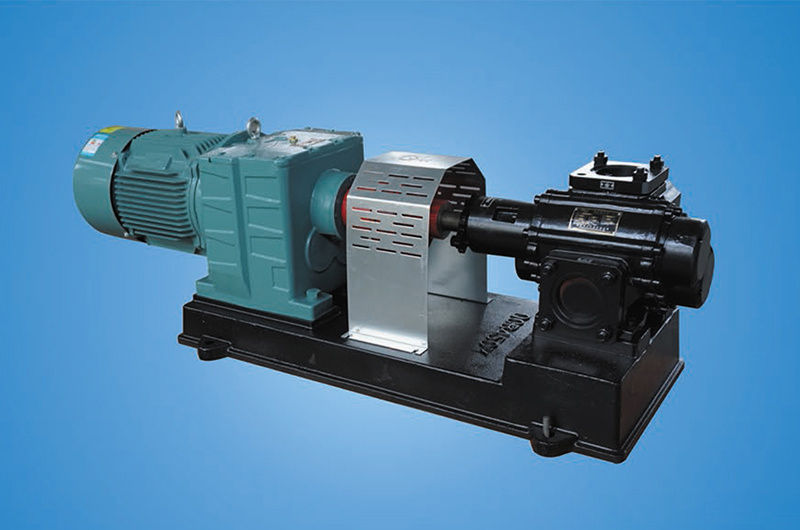

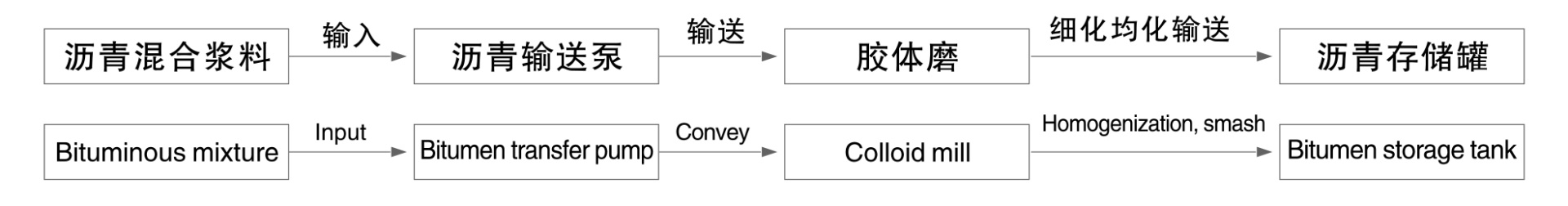

The JMJ type high-speed shear industrial colloid mill is a project developed by our company in collaboration with Professor Tian Guangfa, the designer of China's first SBS modified asphalt mill, using advanced foreign technology. It is a new type of high-efficiency ultra-fine grinder that combines strong extrusion and high-speed shear, mainly used for the high refinement and homogenization of SBS modifiers added to molten asphalt.

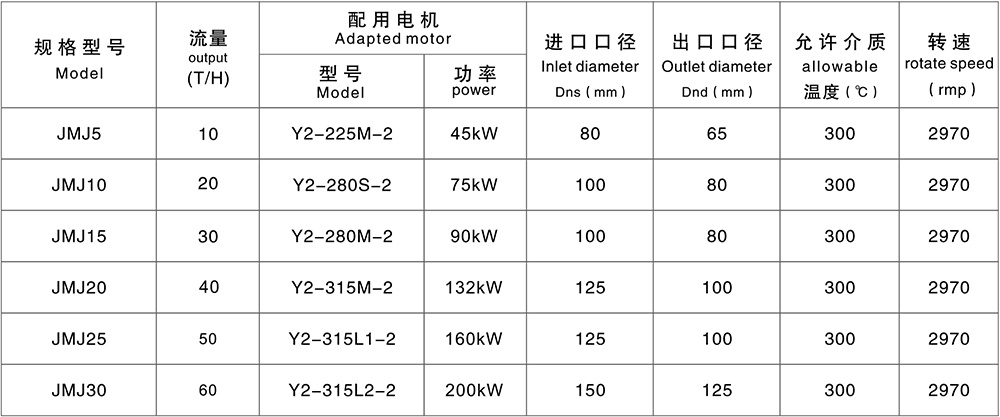

Technical Parameters

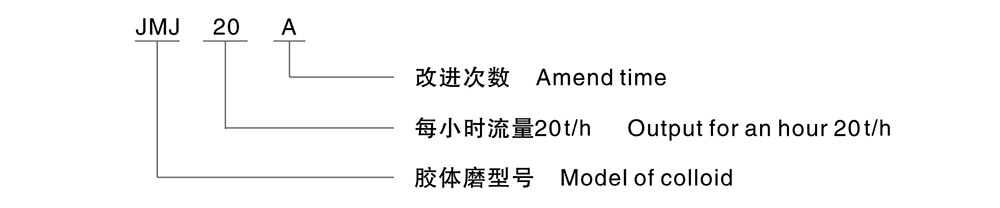

Model Meaning

Working Principle

Structural Introduction

The JMJ type high shear homogenizing colloid mill uses imported spiral high-speed rotation to send the slurry into the gap between the static and dynamic plates. After high-speed grinding between the dynamic and static plates, it enters the tooth ring of the dynamic and static plates for intense shear, achieving high refinement and homogenization of the SBS modifier. In the dynamic and static plates, the JMJ type high shear homogenizing colloid mill adopts a grinding shear cross-type stepped distribution, with increasingly smaller gaps, achieving a fineness of 1~10um for the processed SBS modifier in one pass. The flat tooth structure design of the dynamic and static plates of the JMJ type high-speed shear industrial colloid mill not only simplifies the processing technology, ensures safe use, and maintains high operational precision, but also allows for a larger flow rate. When extruding and shearing SBS short linear materials, the electrical energy, mechanical energy, and thermal energy are all completed within the same mill, saving energy, reducing consumption, and achieving energy-saving effects.

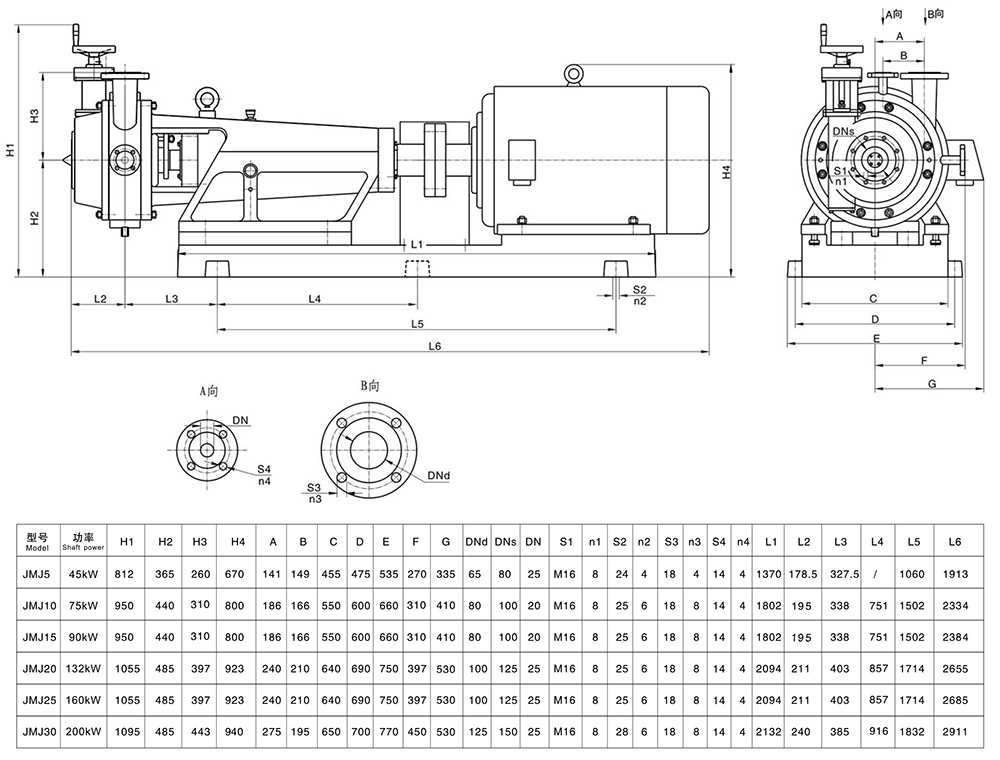

Installation Parameters of JMJ Type High Shear Homogenizing Colloid Mill

Usage and Maintenance

1. Start-up

Before starting production, open the inlet and outlet valves of the JMJ type high shear homogenizing colloid mill (hereinafter referred to as the mill), and inject heat transfer oil into the insulation jacket to preheat the grinding body. Preheating is necessary to avoid stalling and to prevent the grinding body temperature from being too low, which could absorb a large amount of heat from the asphalt, causing the mill to operate abnormally at the beginning or the processed asphalt product to fail to meet standard requirements.

The preheating temperature of the grinding body must be measured with a thermometer, and the medium temperature should be between 170C~180C. Once the grinding body reaches the required temperature, gently rotate the coupling by hand; if the coupling can rotate, the mill can be started. If the coupling cannot rotate, please wait for a while and try to rotate it gently again. If it still cannot rotate, adjust the gap between the dynamic and static plates (according to requirement (3), and note the position at this time), adjust it until the coupling can move, then return to the original position. If it still cannot rotate, please call our service hotline.

During the preheating of the mill, check the oil level of the mill's oil gauge. If the oil level is not visible on the gauge or is very low, oil should be added in time, up to half of the oil gauge.

2. Shut Down

Before shutting down, run ordinary asphalt through the mill.

3. Adjustment of Dynamic and Static Plate Gap

The gap between the dynamic and static plates of the mill has been adjusted to the best position before leaving the factory. Please do not adjust unless necessary (e.g., if the effect is not good after a period of use). If adjustment is needed, please follow the requirements below:

Each time the gap is adjusted, the fastening screws must be loosened. Rotate the scale clockwise to increase the gap and counterclockwise to decrease the gap. Each large scale rotation equals 0.005mm, and each full rotation equals 0.15mm.

4. Equipment Lubrication

Lubricate rolling bearings with cc30 diesel engine oil (GB11122-1997); lubricate the worm gear, worm, and static grinding plate threads with No. 4 high-temperature grease.

Precautions

1. Before starting, the inlet and outlet valves must be opened.

2. It is normal for the packing gland of the spindle to leak before starting; no tightening is necessary. If the leakage is significant, it can be slightly tightened, but it is strictly forbidden to overtighten.

3. When the mill is working, the temperature of the SBS modified asphalt should be between 170C~180C.

4. If any faults are found in the mill, please call our company for repairs. It is strictly forbidden to disassemble without our company's permission; otherwise, the consequences will be borne by the individual.

a simple structure and stable performance. Both the front and rear of the pump are equipped with insulation chambers, allowing gas or liquid to be used as a heat carrier to heat and insulate the pump, making it particularly suitable for transporting high-viscosity media. This series of insulated gear pumps has two inlet and outlet configurations: left inlet and right outlet, and right inlet and left outlet, with the same installation dimensions and strong interchangeability.

Related Products

Online message

* Leave your contact information to get a product quote