High-speed shear industrial colloid mill

Key words:

Classification:

Keyword: High-speed shear industrial colloid mill

E-mail:

Telephone:

Details

Overview

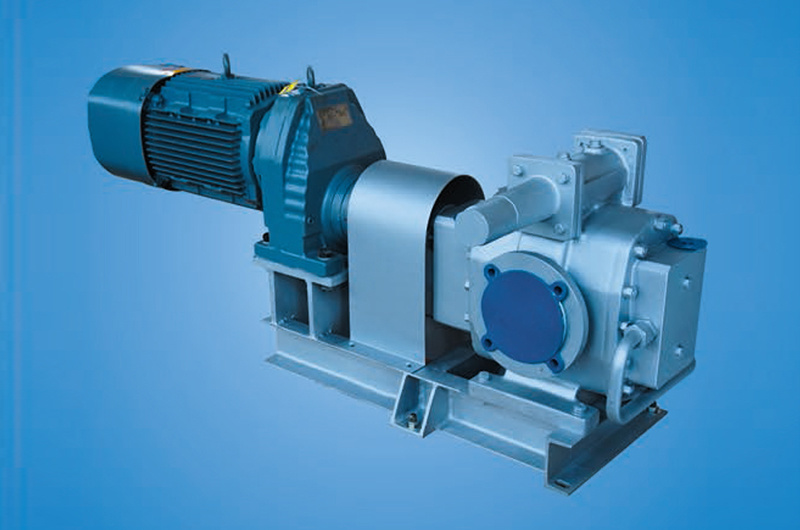

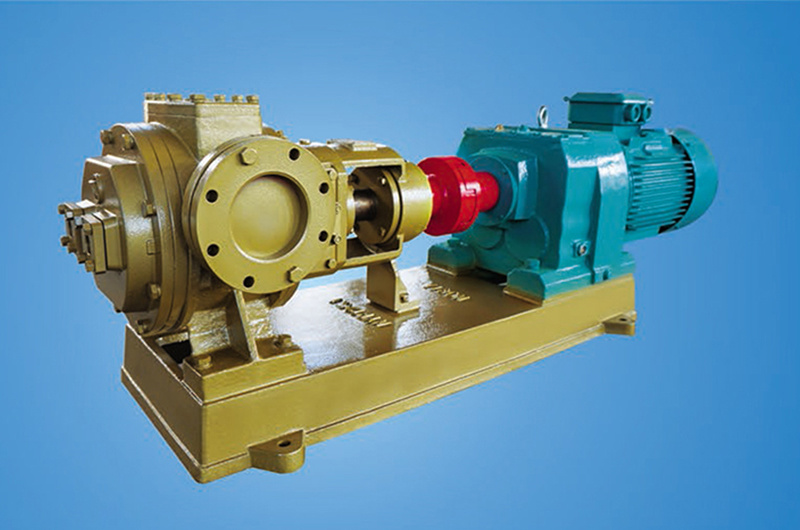

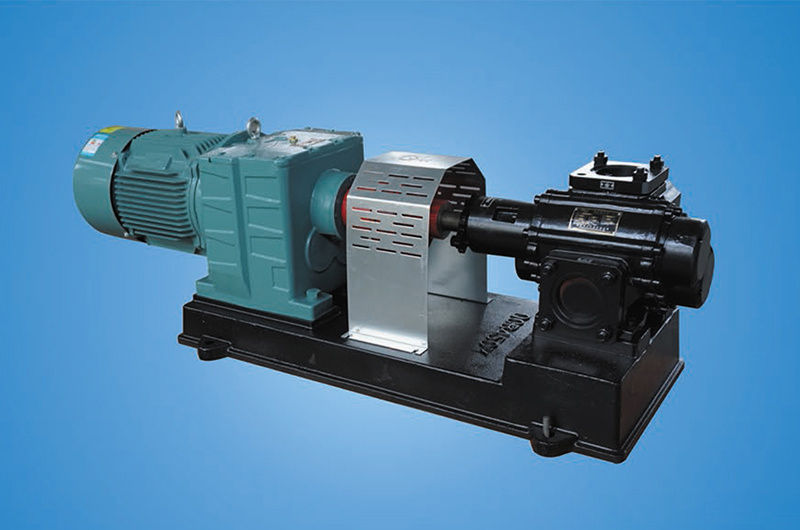

The JMJ type high-speed shear industrial colloid mill is a project developed by our company in collaboration with Professor Tian Guangfa, the designer of China's first SBS modified asphalt mill, using advanced foreign technology. It is a new type of high-efficiency ultra-fine grinder that combines strong extrusion and high-speed shear, mainly used for highly refining and homogenizing the SBS modifier added to molten asphalt.

Structural Introduction

The JMJ type high shear homogenizing colloid mill utilizes imported spiral high-speed rotation to deliver the slurry into the gap between the static and dynamic plates. After undergoing high-speed grinding between the dynamic and static plates, the slurry then enters the tooth ring of these plates for intense shear, resulting in a high degree of refinement and homogenization of the SBS modifier. Within the dynamic and static plates, the JMJ type high shear homogenizing colloid mill features a cross-type stepped distribution for grinding and shear, with progressively smaller gaps, achieving a fineness of 1 to 10 μm for the processed SBS modifier.

The design of the flat tooth structure of the dynamic and static plates of the JMJ type high-speed shear industrial colloid mill not only simplifies the processing technology, ensures safety, and maintains high operational precision, but also allows for a larger flow rate. When extruding and shearing SBS short linear materials, the conversion of electrical energy to mechanical energy to thermal energy is completed within the same mill, saving energy, reducing consumption, and achieving energy-saving effects.

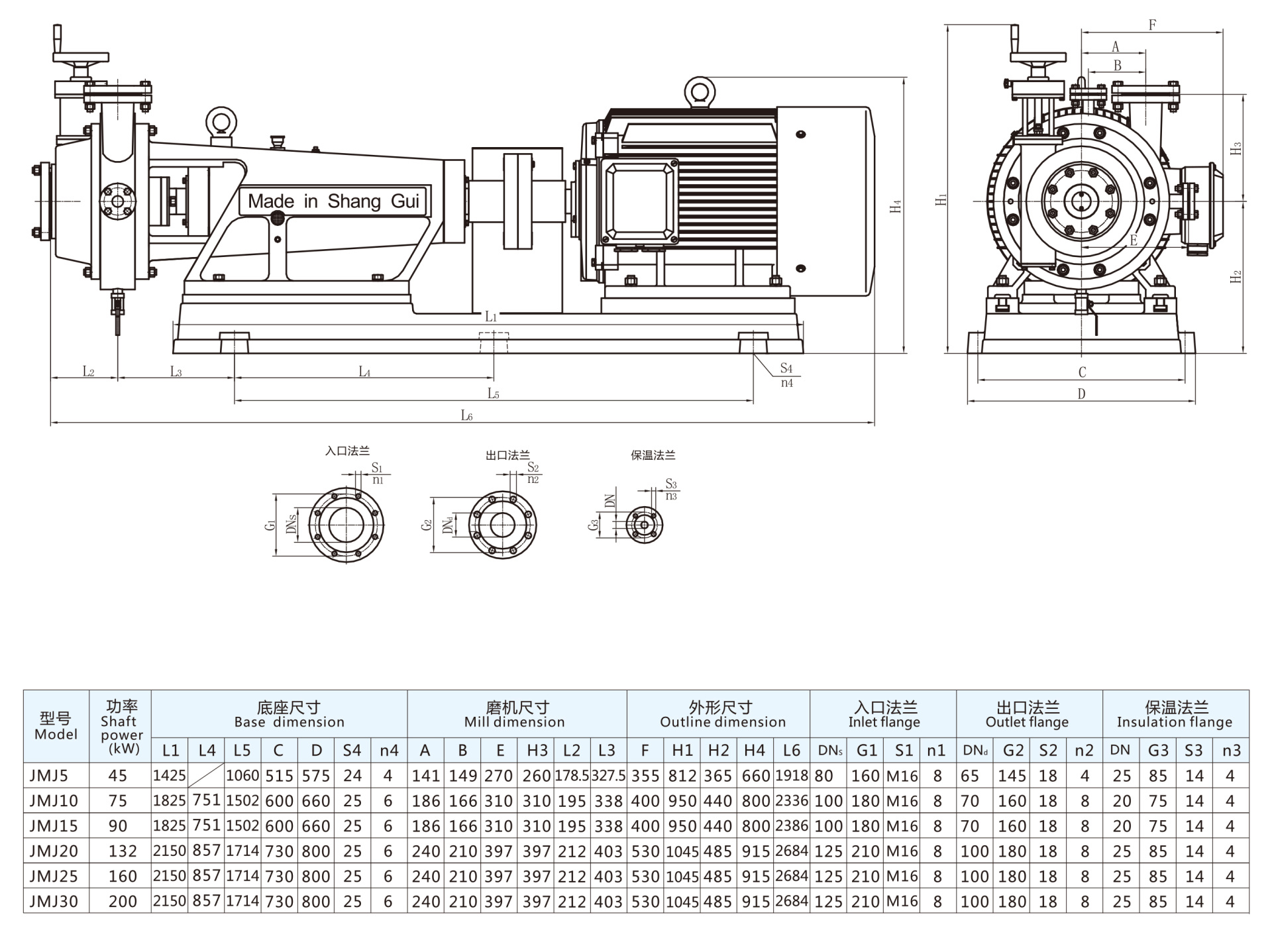

Main Technical Parameters

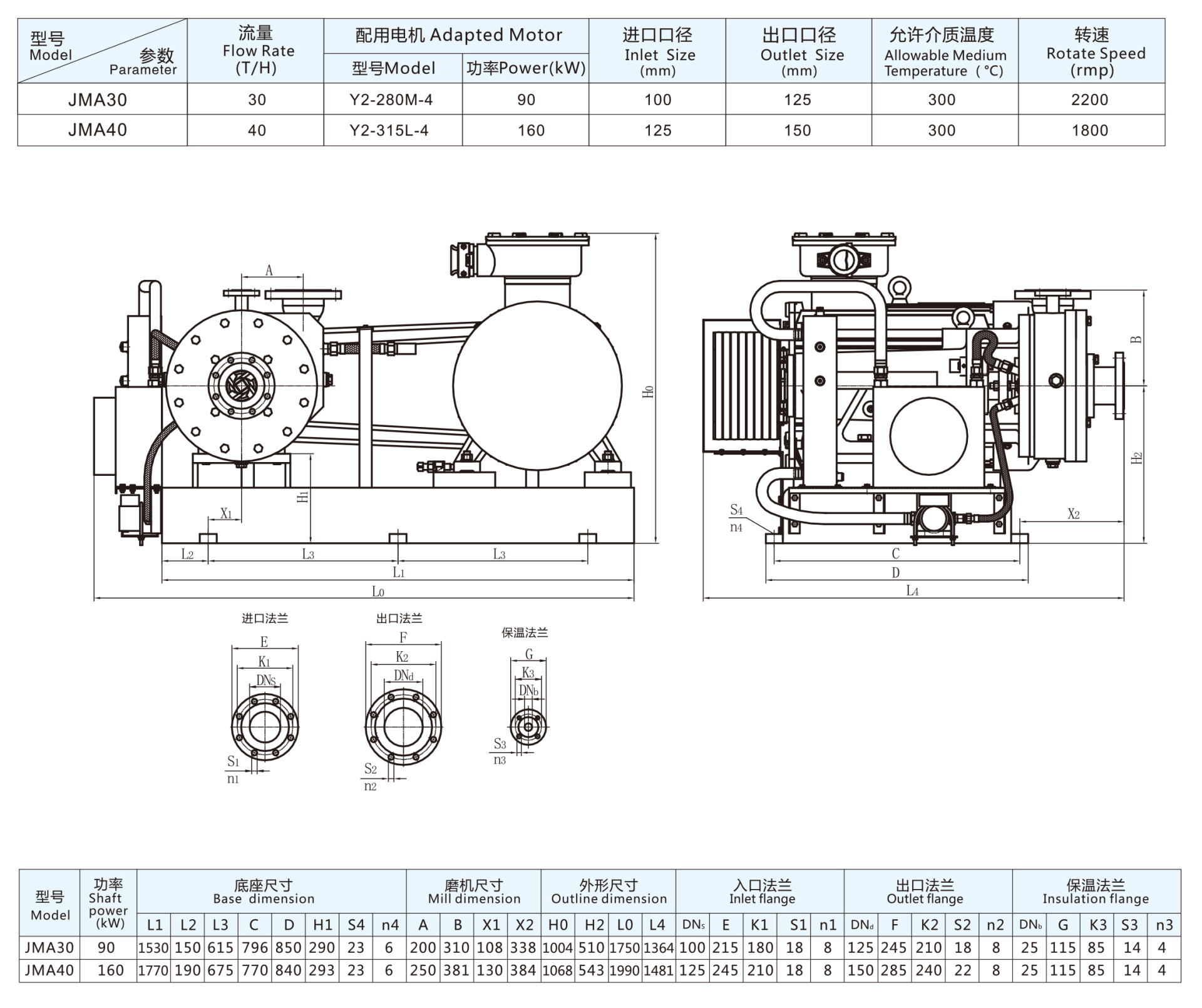

Performance Parameters of JMJ Type High Shear Homogenizing Colloid Mill

|

Parameters Parameter |

Flow Rate Flow Rate (T/H) |

Adapted Motor |

Inlet Diameter Inlet Size (mm) |

Outlet Diameter Outlet Size (mm) |

Permissible Medium Temperature enpe |

Rotate Speed Rotate Speed (rmp) |

|

|

Model |

Power (kW) |

||||||

|

JMJ5 |

10 |

Y2-225M-2 |

45 |

80 |

65 |

300 |

2970 |

|

JMJ10 |

20 |

Y2-280S-2 |

75 |

100 |

80 |

300 |

2970 |

|

JMJ15 |

30 |

Y2-280M-2 |

90 |

100 |

80 |

300 |

2970 |

|

JMJ20 |

40 |

Y2-315M-2 |

132 |

125 |

100 |

300 |

2970 |

|

JMJ25 |

50 |

Y2-315L1-2 |

160 |

125 |

100 |

300 |

2970 |

|

JMJ30 |

60 |

Y2-315L2-2 |

200 |

125 |

100 |

300 |

2970 |

a simple structure and stable performance. Both the front and rear of the pump are equipped with insulation chambers, allowing gas or liquid to be used as a heat carrier to heat and insulate the pump, making it particularly suitable for transporting high-viscosity media. This series of insulated gear pumps has two inlet and outlet configurations: left inlet and right outlet, and right inlet and left outlet, with the same installation dimensions and strong interchangeability.

Related Products

Online message

* Leave your contact information to get a product quote